Key Points for Applying Pesticides in a Greenhouse

Research suggests following pesticide labels for safe and effective use in greenhouses.

It seems likely that wearing proper protective equipment,like gloves and respirators,is essential for safety.

The evidence leans toward using integrated pest management to reduce chemical reliance and environmental impact.

Controversy exists around pesticide residues,so ensure proper ventilation and re-entry intervals for worker safety.

Preparation and Safety

Always read and follow the pesticide label,ensuring it’s approved for greenhouse use and your specific crop.Wear appropriate personal protective equipment(PPE),such as chemical-resistant gloves,boots,coveralls,and respirators if required,to protect against exposure.Have emergency supplies like clean water and eye wash stations ready.

Application Techniques

Apply pesticides only when necessary,based on pest thresholds,and treat small areas to minimize use.Consider integrated pest management(IPM)strategies,combining biological and cultural controls with chemicals.Ensure proper ventilation,especially for fumigants,to manage residues and protect workers.

Environmental and Legal Considerations

Greenhouse coverings,like UV-blocking materials,can affect pesticide degradation,so adjust application rates if needed.Follow Worker Protection Standards(WPS)for re-entry intervals and post warning signs for safety.For restricted-use pesticides,ensure applicators are certified.

Detailed Survey Note on Applying Pesticides in a Greenhouse

This note provides a comprehensive overview of best practices for applying pesticides in greenhouse settings,drawing from authoritative agricultural sources.It aims to ensure safety,efficacy,and environmental responsibility,addressing both practical application and regulatory considerations.The information is current as of June 13,2025,and is intended for greenhouse operators,gardeners,and agricultural professionals.

Introduction

Greenhouses offer controlled environments for plant production but can foster pest development due to warm,humid conditions and the absence of natural predators.Pesticide application is often necessary to manage outbreaks,but it requires careful planning to ensure safety for workers,plants,and the environment.This note compiles detailed tips based on research from agricultural extension services and university guidelines,emphasizing integrated pest management(IPM)and compliance with safety standards.

Preparation and Safety Measures

Label Compliance and Dosage:

The first step is to read and follow the pesticide label thoroughly.Labels typically include a“Directions for Use”section that specifies whether the product is approved for greenhouse application.If the label does not mention greenhouses but lists the crop,it is generally considered an implied use.Apply the exact amount stated on the label to avoid waste,expense,and potential legal issues,as over-or under-application can be illegal in some regions like Oklahoma.

Personal Protective Equipment(PPE):

Wearing appropriate PPE is critical to prevent pesticide exposure,which can occur through inhalation,ingestion,or skin absorption.The label will specify minimum requirements,but generally,include:

Chemical-resistant,unlined gloves free of holes or tears.Wash gloves with detergent and water before removal,and replace worn ones.Tuck gloves inside sleeves when spraying downwards,or wear outside sleeves with a half-inch cuff when spraying upwards.

Chemical-resistant boots,worn inside pant legs,washed and dried after each use.Avoid cloth,canvas,or leather footwear unless covered,as they cannot be fully cleaned of residues.

Clean,dry coveralls(e.g.,Tyvek,Goretex)covering from neck to ankles.Launder separately on a full load cycle in 140°F water with high-phosphate soap,followed by an additional wash/rinse cycle,and air dry(do not use a dryer).Dispose of clothing contaminated with concentrated pesticides immediately.

A waterproof,wide-brimmed chemically resistant hat or cap,avoiding cotton or felt bands,and wash after each use.

Goggles or a full face shield during preparation,spraying,and cleaning,ensuring headbands are non-absorptive.

Respirators,such as cartridge respirators for non-fumigant pesticides(change cartridges after 8 hours or when odors are detected)or gas mask respirators with canisters for fumigants.All respirators must be NIOSH and MSHA approved,with“TC”approval numbers,and require fitting tests and physician exams before use.

Have 5 gallons of clean,fresh water and a squeeze container of liquid dish detergent at the application site,along with a portable eye wash for emergencies.Never eat,drink,or smoke while mixing or applying pesticides,and keep food and beverages away from storage and treated areas,designating a separate break area for workers.

Worker Training and Certification:

Conduct safety training before the greenhouse season,covering PPE use,restricted-entry intervals(REIs),treated areas,and Worker Protection Standards(WPS)requirements.Display a list of pesticide applications,including location,time,date,product name,EPA registration number,active ingredients,and REI,for worker reference.Obtain WPS materials from local County Extension Offices or Department of Agriculture inspectors.For restricted-use pesticides,nursery/greenhouse growers must be certified in the Nursery Greenhouse category(3c)as non-commercial or commercial applicators if for hire,with information available from local Cooperative Extension Offices or state agriculture departments.

Emergency Preparedness:

Post emergency contact numbers,such as the Oklahoma Poison Control Center(1-800-522-4611),National Pesticide Telecommunications Network(1-800-858-7378),National Response Center(1-800-424-8802),Department of Environmental Quality Hotline(1-800-522-0206),CHEMTREC(1-800-424-9300),and Pest Management Section,Dept.of Agriculture(405-521-3864).Have first-aid procedures ready,including removing contaminated clothing,washing with soap and water,and accessing eye wash/showers.Train at least one employee in CPR,and refer to extension fact sheets like EPP-7453 for first-aid overviews.

Monitoring for Overexposure:

For workers regularly using organophosphates or carbamates,establish a cholinesterase baseline through blood tests for pseudocholinesterase and/or Red Blood Cell(RBC)acetylcholinesterase enzyme activity,ideally before the major spray season or after 3-4 weeks without exposure.Conduct weekly or bi-weekly tests to identify overexposure,discussing testing accuracy with a physician.This is particularly important for applicators using these chemicals,as individual differences in cholinesterase levels can affect safety.

Application Techniques and Environmental Considerations

Integrated Pest Management(IPM):

Adopt IPM strategies to reduce reliance on chemical pesticides,combining biological controls(e.g.,beneficial organisms),cultural practices(e.g.,sanitation),and chemical treatments.Monitor pests regularly using sticky cards and plant inspections to justify treatments based on thresholds.Treat small areas or individual plants when possible,rather than the entire greenhouse,to minimize pesticide use.Avoid persistent compounds and slow-release/encapsulated formulations,as ideal insecticides should kill pests quickly and then degrade to reduce environmental impact.Limit the frequency of treatments,particularly nerve toxins,and evaluate cost-benefit economics to ensure efficacy.

Preventing Pest Introduction:

Stock plants with dense canopies may reduce spray penetration,so consider integrated approaches like beneficial organisms for efficacy.Remove broadleaf weeds from the greenhouse perimeter and indoor production areas,using grass,gravel,or weed barriers under benches to minimize weed pressure,as weeds can serve as pest sources.Dip unrooted cuttings and plugs into reduced-risk pesticides to lower the number of pest hitchhikers entering the greenhouse.

Greenhouse Environmental Factors:

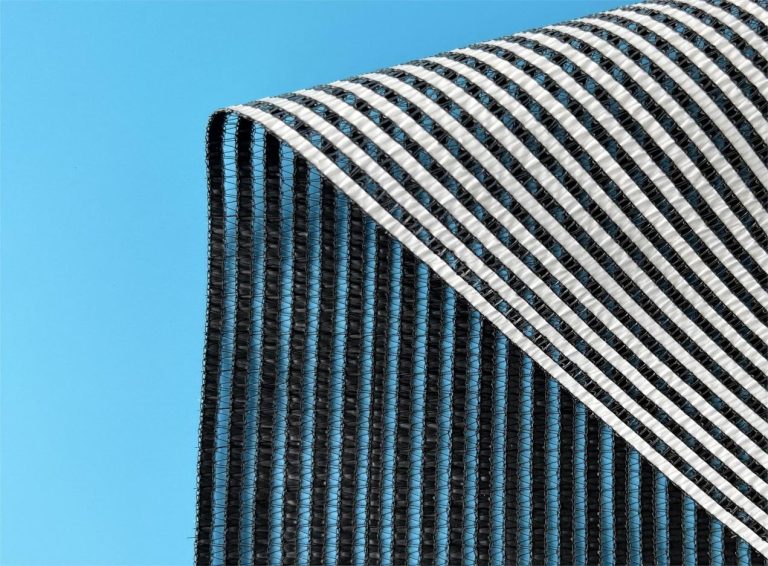

The type of greenhouse covering affects pesticide degradation.UV-blocking materials(e.g.,fiberglass,polycarbonate,treated polyethylene)remove light between 10 and 400 nm,increasing pesticide residual activity by slowing degradation.Adjust application rates or frequencies accordingly.In contrast,glass,acrylic sheeting,and untreated polyethylene films allow the full light spectrum,which can degrade pesticides faster.This is particularly relevant for foliar-applied pesticides,which may have longer residuals in UV-blocked settings.

Ventilation and Re-Entry Intervals(REIs):

Greenhouses are defined as“enclosed space production”under WPS if covered by nonporous materials(e.g.,poly film hoop houses,even with open sidewalls),with porous materials like certain polyethylene(PE),polypropylene(PP),polyvinylidene fluoride(PVDF),polytetrafluoroethylene(PTFE),and ethylene-vinyl acetate(EVA)lacking specific guidance but treated as enclosed.Follow ventilation criteria after application,such as 10 air exchanges,2 hours of mechanical ventilation,4 hours of passive ventilation,11 hours without ventilation plus 1 hour mechanical,11 hours without ventilation plus 2 hours passive,or 24 hours without ventilation.For REIs,follow specific rules:

Fumigants:Restrict the entire space until ventilation criteria are met or the REI expires(e.g.,48-hour REI,ventilate 24 hours,wait another 24 hours).

Fine droplets(≤293 microns,no respirator):Restrict the space until ventilated or REI expires(e.g.,4-hour REI,ventilate or wait 24 hours).

Fine droplets(≤293 microns,requires respirator):Restrict the space until ventilated,treated area until ventilated or REI expires.

Medium droplets(>294 microns,>12 inches from media):Restrict treated area+25 feet until application complete,then REI applies,no ventilation needed.

Medium droplets(>294 microns,<12 inches from media):Restrict treated area until REI expires,no ventilation needed.

Post warning signs if REI>4 hours in enclosed space or>48 hours outdoors;otherwise,oral warning or sign is allowed.Dual notification(sign and oral)is required if specified on the label,regardless of REI.

Legal and Regulatory Compliance

Ensure all pesticide applications comply with local regulations,including licensing for restricted-use pesticides.For example,in Oklahoma,nursery/greenhouse growers applying such pesticides must be certified in category 3c,with information available from local Cooperative Extension Offices or state agriculture departments.Always verify product labels for specific crop and greenhouse use,downloading tables like those at Michigan State University Extension-Vegetable Pesticide Series:Can I Use It in the Greenhouse?for guidance(e.g.,“yes”for all uses,“no”for disallowed,“avoid”for cautions,“certain crops only,see label,”or“silent”for implied use).

Table: Summary of Pesticide Application Tips

| Category | Key Tips |

|---|---|

| Preparation | Read label, wear PPE (gloves, boots, coveralls, respirators), have emergency supplies. |

| Application | Use IPM, treat small areas, monitor pests, avoid persistent compounds. |

| Environmental Factors | Adjust for UV-blocking materials, ensure ventilation, follow REIs. |

| Safety and Compliance | Train workers, post warning signs, certify for restricted-use pesticides. |

| Health Monitoring | Test cholinesterase levels for organophosphate/carbamate users. |

Conclusion

Applying pesticides in greenhouses requires careful attention to safety, environmental impact, and regulatory compliance. By following label instructions, using IPM strategies, and ensuring proper ventilation and worker protection, greenhouse operators can manage pests effectively while minimizing risks. Regular monitoring and training further enhance safety and efficacy, ensuring a sustainable approach to pest management.