Why Dehumidify Multi-Span Film Greenhouses?

Multi-span film greenhouses, with their connected bays covered in plastic sheeting, create enclosed environments ideal for crop growth but prone to high humidity from plant transpiration, irrigation, and condensation on the film. Excessive humidity (above 80-85% relative humidity, or RH) can promote fungal diseases like botrytis, reduce pollination, and lower yields. Effective dehumidification maintains optimal RH (typically 60-80% depending on crops) and vapor pressure deficit (VPD) for healthy plants. Strategies range from low-cost passive methods to advanced mechanical systems, prioritized by energy efficiency and greenhouse design.

Step-by-Step Guide to Dehumidification

Follow these steps progressively, starting with preventive and low-energy options before investing in equipment. Multi-span designs often feature roll-up sidewalls, roof vents, and gutters, making ventilation highly effective.

Step 1: Prevent Excess Moisture Buildup (Low-Cost, Foundational Practices)

Address sources of humidity before it accumulates:

- Switch to Drip Irrigation: Deliver water directly to roots to minimize evaporation and leaf wetting. Time watering for mornings to allow drying before night.

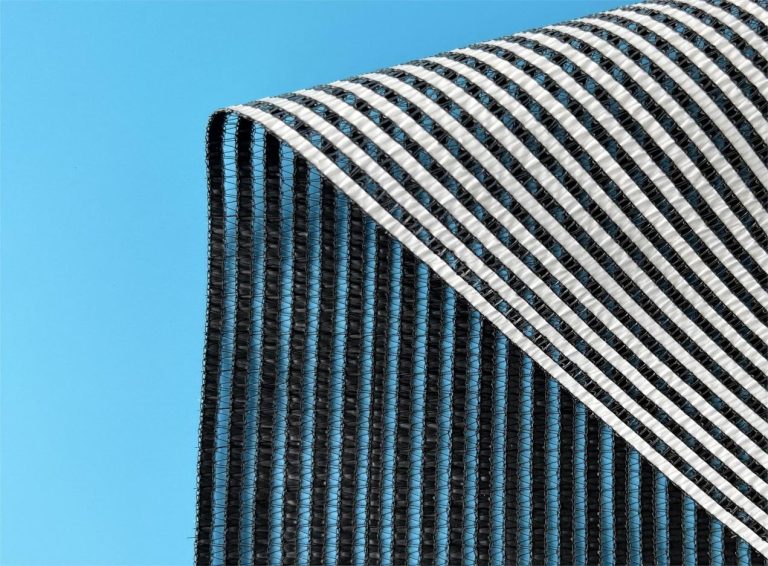

- Mulch Soil Surfaces: Cover bare soil with plastic film, straw, or wheat straw to reduce evaporation by up to 50%. This is especially useful in film greenhouses where soil moisture contributes significantly to air humidity.

- Reduce Plant Density: Space plants 10-20% farther apart (e.g., for cucumbers) to limit transpiration and improve airflow.

- Drain Condensate Promptly: Install gutters or slopes on film covers to channel dew away from plants, preventing drips that reintroduce moisture.

Step 2: Enhance Air Movement and Circulation

Stagnant air traps humidity; circulation evens it out without energy loss:

- Use Fans for Internal Circulation: Install horizontal (ceiling) or vertical (floor-to-ceiling) fans to mix air, raise leaf temperatures, and dry surfaces. Aim for 0.15-0.25 m/s airflow speeds in multi-span bays.

- Timed Vent Adjustments: Automate side and roof vents to open at sunrise (when RH peaks) and close midday. In multi-span setups, coordinate vents across spans for uniform flow.

Step 3: Apply Temperature and Ventilation Techniques

Leverage the greenhouse’s natural dynamics:

- Heat and Vent Cycle: Raise air temperature to 28-30°C (using heaters or solar gain) to boost its moisture-holding capacity, lowering RH. Then ventilate to expel humid air. Repeat every 3-4 hours if needed, but monitor to avoid chilling plants.

- Natural Ventilation: Open roll-up sides or roof vents during warm periods (above 20°C outside) for passive exchange. In multi-span film greenhouses, this can reduce RH by 10-15% quickly but close vents if outdoor air is cooler to prevent condensation.

- Absorbent Materials: Spread quicklime, straw, or hygroscopic non-woven fabrics between rows or on thermal curtains to naturally absorb fog and vapor.

Step 4: Implement Mechanical Dehumidification (If Needed for High-Humidity Climates)

For persistent issues (e.g., in humid regions or year-round production), add targeted systems:

- Automated Fan-and-Pad Systems: Use exhaust fans with evaporative pads to pull in dry air and push out moist air, dropping RH from 90% to 75% in minutes. Integrate humidity sensors for automation.

- Heat Exchangers: Add to ventilation systems to recover 40% of heat lost during venting, improving efficiency in colder climates.

- Ventless Dehumidifiers:

- Refrigeration/Heat Pump Units: Cool air to condense moisture (collected for reuse), then reheat it. Energy-efficient (>100% recovery) and CO2-retaining; ideal for sealed multi-span greenhouses.

- Desiccant (Chemical) Systems: Use salt solutions to absorb moisture, regenerating with low-heat sources. Saves 10% energy vs. basic venting but best for moderate humidity.

- Condensation Systems with Outdoor Air: In cooler climates, use fan-coil units drawing cold exterior air to condense indoor moisture.

| Method Category | Pros | Cons | Best For Multi-Span Film GH |

|---|---|---|---|

| Preventive (Mulch, Drip) | Low cost, easy implementation | Doesn’t address existing humidity | All sizes; prevents soil-based moisture |

| Ventilation/Circulation | Energy-efficient, uses existing structure | Weather-dependent; may introduce pests | Large spans with vents; quick RH drops |

| Temperature Management | Improves plant growth alongside dehumidification | Requires heating energy | Sunny climates; repeatable cycles |

| Mechanical Dehumidifiers | Precise control, works in any weather | High upfront cost (payback 3-9 years) | High-value crops; humid/tropical areas |

Monitoring and Optimization Tips

- Track Metrics: Use sensors for RH, temperature, and VPD (aim 0.45-1.25 kPa). Apps or controllers can automate responses.

- Crop-Specific Adjustments: Lower RH for fruiting stages (e.g., tomatoes at 65%) vs. vegetative (80%).

- Energy Savings: In multi-span designs, zone controls (e.g., per bay) reduce overall use. Combine methods—e.g., mulch + fans—for 20-30% better efficiency.

- Common Pitfalls: Avoid over-venting in cold weather, which spikes energy use, or ignoring film tears that leak humid air.

Consult local extension services for site-specific advice, as climate and crop type vary. With these steps, you can maintain a healthier, more productive greenhouse.